QUICK CONTACT

Feel free to ask any questions over the phone, or get in touch via our contact form below. Your message will be dispatched directly to our staff who will answer as soon as they can.

EM RIBBED WIRE MESH – STANDARD SHEET & CUT TO SIZE MESH

EM RIBBED WIRE MESH is a steel reinforcement material in concrete. The mesh is used for replacing the traditional “cut & bend” and placing of steel thermo-mechanical treated bars. The mesh is an electric fusion welded prefabricated reinforcement consisting of a series of parallel longitudinal wires with accurate spacing welded to cross wires at the required spacing. Machines are used to produce the mesh with precise dimensional control. The product results in considerable savings in time, labour and money.

EM RIBBED WIRE MESH compliance to MS145, CIDB and ISO9001 STANDARD

Uses of EM RIBBED WIRE MESH

The welded wire mesh is made up of low carbon steel wire and available in various sizes and shapes. It is widely used in construction industry mainly in Reinforce Concrete Slab & Wall, Precast Components and Infrastructure as well. It is also used in mines, gardening, machine protection and other decorations.

Specification

| Diameter (mm) | Yield Strength (N/mm2) | Tensile Strength (N/mm2) |

| 4mm - < 8mm | 500 N/mm2 | 510 N/mm2 |

| ≥ 8mm – 13mm | 500 N/mm2 | 525 N/mm2 |

EM RIBBED WIRE MESH – STANDARD SHEET

EM Standard Sheet Wire Mesh is manufactured in sheet form Standard Mesh which is 6.00 metres length by 2.20 metres width.

Mesh Type: A, B, C, DA & E (Refer Standard Mesh Table)

EM RIBBEB WIRE MESH – CUT TO SIZE

EM Cut to Size Wire Mesh is a special configured mesh whereby each piece of mesh can be produced with a combination of different wire diameter, spacing and dimensions. The wire can also be arranged in staggered or twin wire form. This special configured mesh is produced to suit certain specific design requirement, and could be used with considerable steel saving in any reinforcement concrete structures. It also comes with design drawings and customized special run mesh.

Advantages Of EM Cut To Size Wire Mesh

- Minimized the percentage of wastages and supervision of labour

- Boost the speed of construction

- Reducing on site labour

- Better utilization of on-site space and logistics

- Able to cut and bend to suit specific design requirements

Mesh Size: Special configuration of wire diameters and/or wire spacing (Refer Standard & Special Mesh Table)

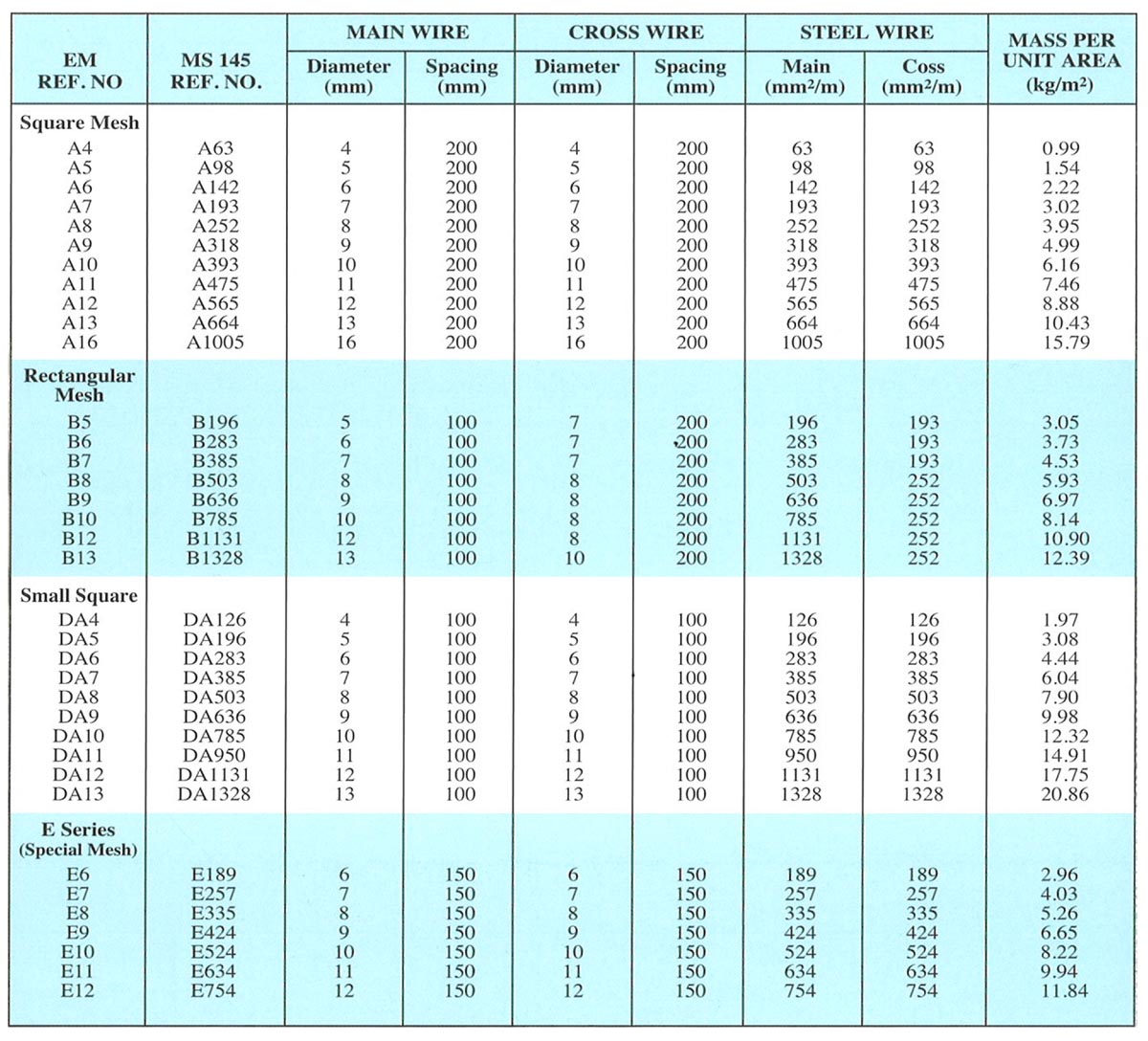

EM Ribbed Steel Fabric (Grade 500A)

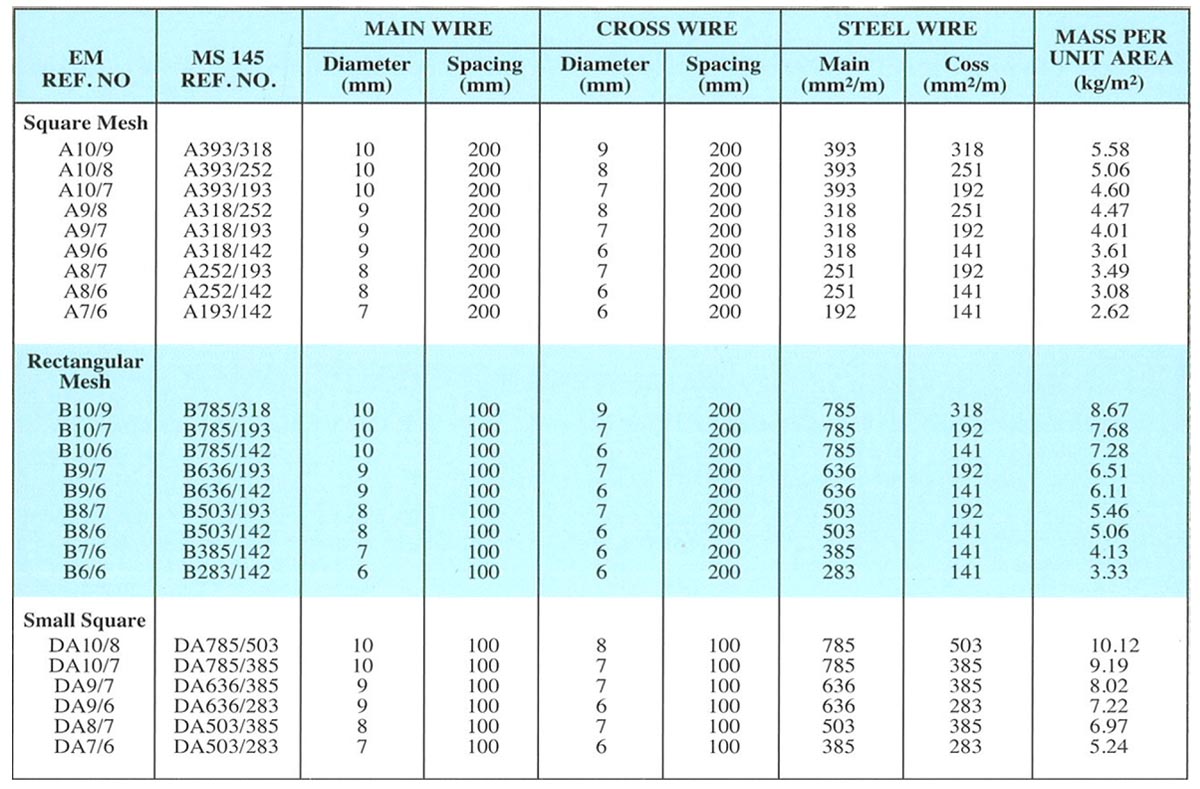

EM Ribbed Special Steel Fabric (Grade 500A)

Note: If there is requirement on special mesh / double mesh wire, can contact our staff for further details.

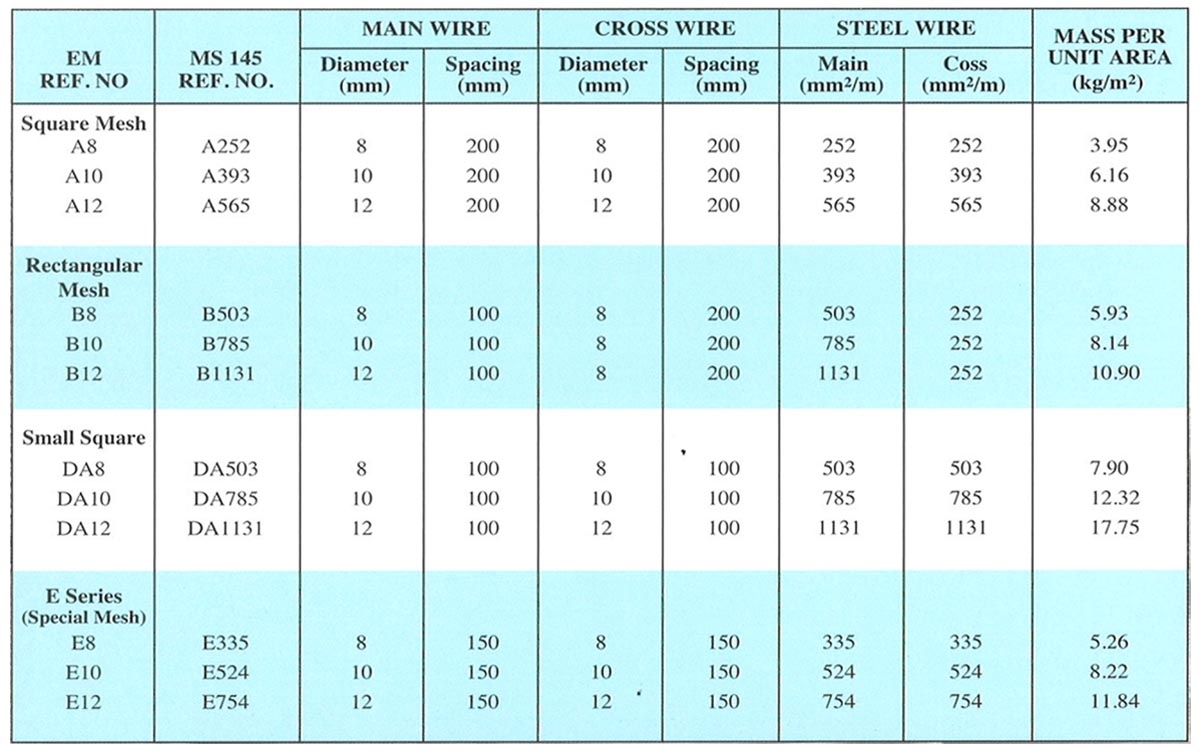

EM Ribbed Steel Fabric (Grade 500B)

Note: If there is requirement on special mesh / double mesh wire, can contact our staff for further details.

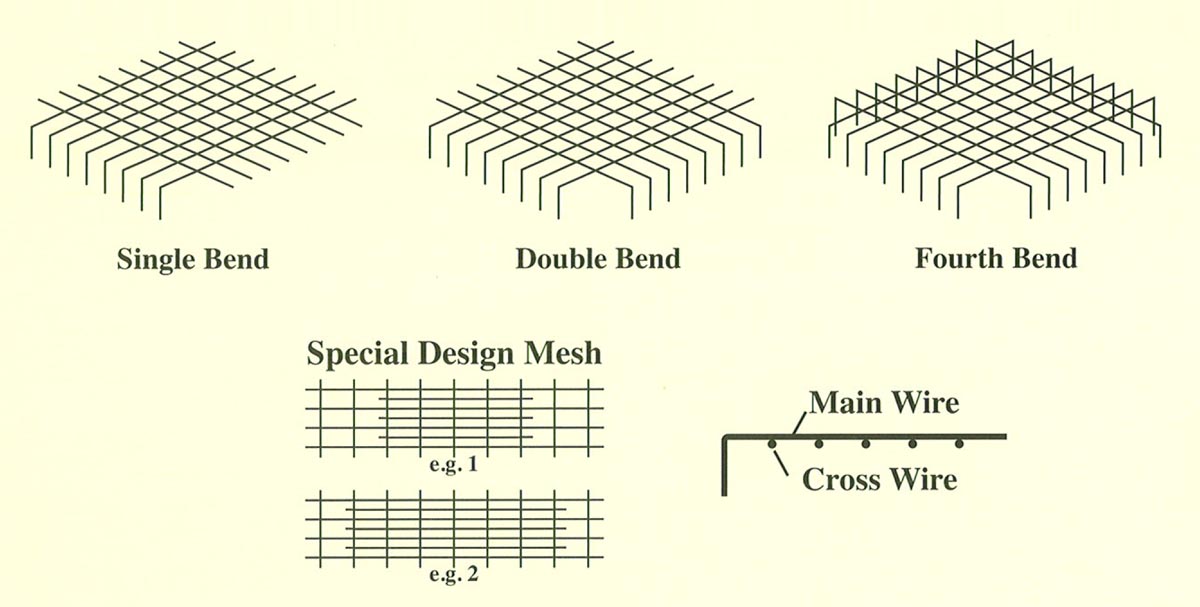

EM Types of Bending and Special Design Mesh